ROForm - Resource Optimized Forming

Research project at a glance

Funding type

Period

01.03.2021 to 29.02.2024

Project Description

In modern society, plastic packaging fulfills important functions for consumers and industry and is indispensable in everyday life: easy and inexpensive to produce in large quantities, it significantly simplifies handling during transport and storage and extends the shelf life of food up to three times. At the same time, the consumption and use of plastics are being increasingly criticized in public because of the environmental problems they cause: In addition to known problems - such as weaknesses in recycling and disposal concepts or the proliferation of (micro)plastics in the marine environment - the production of plastics and the incineration of plastic waste were associated with global emissions of around 400 million tons of CO2 annually as early as 2012, according to EU figures.

The Plastics Strategy presented by the EU Commission in 2018 therefore envisages a more circular economic system that focuses increasingly on reuse, repair and recycling. An important field of action associated with this is the reduction of plastic use through weight- and recycling-optimized product design and optimized production processes.

In the ROForm project, processes are being developed to minimize the energy and material input for thin-walled plastic packaging produced either by extrusion blow molding (bottles, canisters, IBCs) or by thermoforming (blister packs). This is expected to result in a significant reduction in CO2 emissions, which will help to achieve the EU's climate targets.

climate targets. Furthermore, lighter articles and shorter production times will reduce

production costs are reduced and the competitiveness of the companies involved is secured. Consumers benefit through reduced prices and lower waste disposal costs.

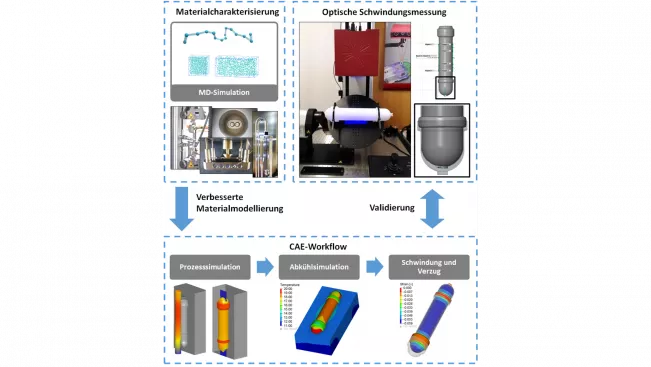

The solution lies in a further development of the CAE development chain for thin-walled plastic parts. For the companies involved, the application and use of such development chains are an important building block in securing their locations and competing with companies, particularly from Asia.

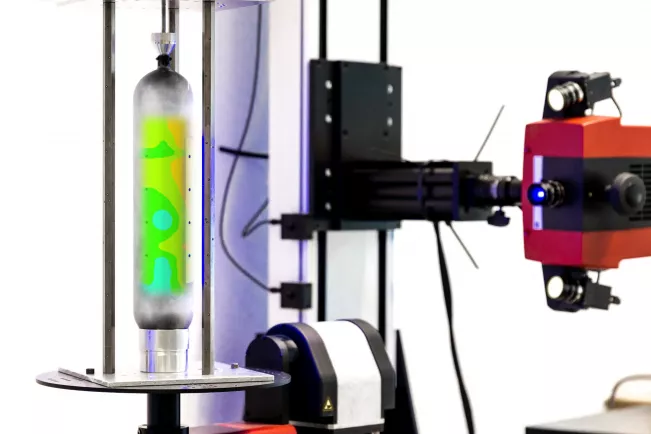

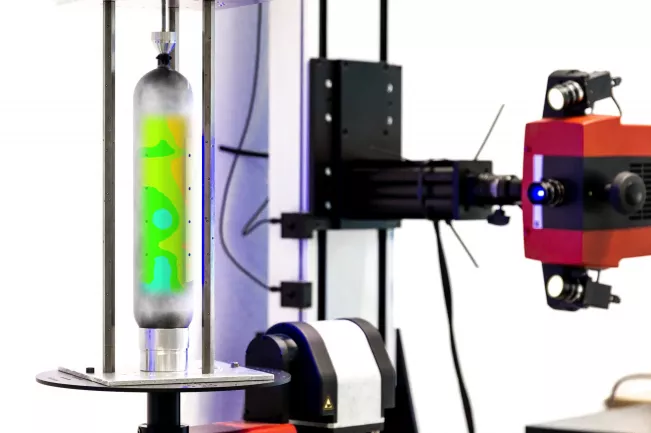

The aim of the project is to significantly improve the prediction of shrinkage and warpage of blow-molded and thermoformed articles by means of simulation methods compared with the state of the art. The use of the deformed geometry in conjunction with improved material descriptions increases the prediction accuracy of subsequent simulations and leads to resource-optimized design, energy savings in the production process and lower development costs.

For the first time, the experimental determination of material properties is complemented by molecular dynamics (MD) simulations, which enables their determination in application conditions that are hardly accessible experimentally. Another essential goal is the coupling of MD and FEM simulation to a new closed simulation chain. This allows to better exploit the potentials of both simulation methods.

Publications

Cooperation partners

Sponsors

Links

Related links