Department of Engineering and Communication

Prof. Dr Olaf Bruch

Engineering mechanics, finite element methods and polymer materials

Unit

Department of Engineering and Communication, Institute of Technology, Resource and Energy-efficient Engineering (TREE)

Location

Sankt Augustin

Room

B 203

Address

Grantham-Allee 20

53757 Sankt Augustin

Telephone

+49 2241 865 318Profile

Teaching areas:

- Engineering Mechanics

- Finite Element Method (FEM)

- Structural optimization

Fields of work:

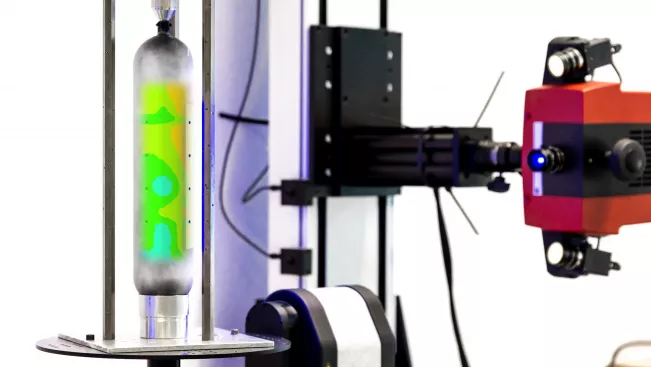

- Integrative simulation of plastic components

- Prediction of shrinkage and warpage in extrusion blow molding

- Development of experimental and numerical methods for the identification of material parameters for FE structural analysis

- Fluid-structure coupling (FSI): simulation of the behavior of liquid-filled containers

- Structural optimization of generatively manufactured components u

Co-Affiliation:

Research Projects

The "Digital Twin-4-Multiphysics Lab" (DT4MP) focuses on urban digital twins (UDTs) and multiphysics twins for industry, treating both areas equally and synergistically. By integrating real-time data and advanced simulations, DT4MP enhances urban processes, infrastructures, and industrial production efficiency. Combining AI and machine learning, the lab provides services like data analysis and virtual testing for SMEs and larger companies. Founded by leading institutes, DT4MP drives digitalization research in urban and industrial contexts.

Project management at the H-BRS

Prof. Dr Sebastian Houben Prof. Dr Dirk Reith Dr Alexander HaggIn modern society, plastic packaging fulfills important functions for consumers and industry and is indispensable in everyday life: easy and inexpensive to produce in large quantities, it significantly simplifies handling during transport and storage and extends the shelf life of food up to three times.

Project management at the H-BRS

Prof. Dr Christian Dresbach Dr Esther van DorpThe institute TREE operates the TREE-Energy Lab (TRE3L) in the university's Center of Applied Research (ZAF) with it's industrial partners GKN Driveline and GKN Sinter Metals. In the three sub-labs Powder Fabrication-Lab, Mobility-Lab and Hydrogen-Lab the three partners work on innovative techniques in powder metallurgy and recent topics of environment friendly mobility and energy-efficiency. These labs are supported by a Simulation-Lab.

Project management at the H-BRS

Prof. Dr Alexander Asteroth Prof. Dr Tanja Clees Prof. Dr Dirk ReithPublications

Selected publications and conference papers

- Michels, P., Bruch, O., Evers-Dietze, B., Grotenburg, D., Ramakers van Dorp, E., Altenbach, H: Shrinkage simulation of blow molded parts using viscoelastic material models, Materialwiss. Werkstofftech. 2022, 53, 449, doi 10.1002/mawe.202100350

- Grommes, D., Schenk, M., Bruch, O., Reith, D.: Investigation of Crystallization and Relaxation Effects in Coarse-Grained Polyethylene Systems after Uniaxial Stretching. Polymers. 13(24): 4466, 2021, doi 10.3390/polym13244466

- Bruch, O., Grommes, D., Michels, P., Busch, A., Ouali., A.: An integrative optimization concept for extrusion blow molded parts. Proceedings of NAFEMS World Congress 2021, 25-29.10.2021

- Bruch, O., Michels, P., Grotenburg, D.: Enhanced Simulation of Shrinkage and Warpage of Extrusion Blow Molded Parts Using the VMAP Interface Standard, Conference Proceedings of 1st International Conference on CAE Interoperability 2020

- Bruch, O., Michels, P., Grommes, D., The simulation and optimization workflow for extrusion blow molded parts and how it benefits from the VMAP Interface Standard, Präsentation und Veröffentlichung auf der Fachtagung 3DEXPERIENCE Conference, 19.11.-21.11.2019, Darmstadt

- Michels, P.; Bruch,O.; Evers-Dietze, B.; Ramakers van Dorp, E.; Altenbach, H., Simulation of shrinkage and warpage of extrusion blow molded parts, Präsentation und Veröffentlichung auf der Fachtagung 3DEXPERIENCE Conference, 19.11.-21.11.2019, Darmstadt

- Michels, P.; Bruch,O.; Evers-Dietze, B.; Ramakers van Dorp, E.; Altenbach, H.: Simulative und experimentelle Bestimmung der Bauteilschwindung von extrusionsblasgeformten Kunststoffhohlkörpern, Tagungsband 14. Magdeburger Maschinenbautage, pp. 198–208, 2019

- Michels, P.; Grommes, D.; Oeckerath, A.; Reith, D.; Bruch, O.: An integrative simulation concept for extrusion blow molded plastic bottles, In: Finite Elements in Analysis and Design 164, 2019, pp. 69-78

Links

Weiterführende Links