Institute of Technology, Resource and Energy-efficient Engineering (TREE)

Dynamics Lab

Vibration analyses

A variety of vibration analyses can be carried out in the H-BRS dynamics laboratory. An electrodynamic shaker with a maximum payload of 150 kg is available for vibration excitation. Vibration analysis is carried out either classically via acceleration measurement and modal analysis in order to analyze the movement patterns in various resonance states or via optical 3D measurement using a high-speed camera.

Accompanying measurement tasks and load simulations

The loads can also be measured using strain gauges. Most of the available measuring equipment can also be used as mobile equipment for external measuring tasks. Typical tasks that have been dealt with so far are the identification of noise sources, investigation of the transmission behavior of materials, analysis of movement patterns that are not visible to the naked eye, as well as load simulations and analysis of the long-term effects, for example for electronics or plastic components.

„Anything that vibrates, squeaks and rattles is unpleasant for people and, in case of doubt, means unnecessary stress and wear for the machine. We help with the investigation of vibration behavior, the search for weak points or the analysis of suitable components that can withstand or prevent vibrations.”

Prof. Dr. Iris Groß - Professor for technical mechanics, construction elements, CAD

Industrial services

In the field of industrial services, we receive inquiries from customers ranging from small companies to large corporations in the automotive, computer and electrical engineering and rubber industries. Please do not hesitate to contact us if you have specific research ideas or need support with entrepreneurial challenges. With vibration testing systems of various sizes, laser vibrometers and a high-speed camera system that can optically record the deformation of components under load, we are ideally equipped to analyze dynamic load cases. For example, the functioning of digital and electrical components under various vibration loads was investigated. Other examples of practical and model computer simulations include noise analyses on drive trains of cars and agricultural machinery, as well as the determination of the damping properties of rubber parts and the development of test methods to determine the sound insulation properties of entire cars. Individual analysis tools can be developed and implemented for the damage assessment of test parts. Off-site measurements for larger or fixed components and machines for vibration analysis are also possible.

You can contact us with the following questions:

- Vibration measurement tasks (internal and external)

- Modal analysis: e.g. search for noise sources (internal and external)

- Investigation of the transmission behavior of materials: e.g. rubber-elastic parts (internal)

- Acceleration and strain measurements with strain gauges (internal and external)

- Load analyses on the shaker (internal)

- Optical 3D measurements to investigate vibration behavior: high-speed camera, tracking system

Previous research tasks from the industry:

- Load simulation for electronic components

- Vibration analysis with the use of strain gages

- Determination of damping properties of rubber parts

- Determination of wear on bearing seats under the influence of vibration

- Analysis of movement patterns under the influence of vibration (camera-supported)

- Determination of dynamic stiffness of elastomer bearings

- Modal analysis of AdBlue® tanks

- Operational vibration analysis

Equipment dynamics lab H-BRS

On this page you will find information on the following equipment:

- Vibration testing systems TV 56263 / LS-340, TV 51144 / S 540, LDS V555

- Laser vibrometer PDV100

- Piezoelectric vibration generator Wilcoxon Research modal F7

- Fastcam SA3 - High speed camera

- Zeiss ARAMIS - Digital image correlation: SRX camera system/ 5M camera system

- GOM TRITOP

Equipment Vibration testing systems

Vibration test system TV 56263 / LS-340

- Nominal force (N): Sine/noise/shock 6300/4300/13500

- Frequency range (Hz): 5-3000

- Max. Vibration displacement (mm): Peak - Peak 50.8

- Max. Acceleration (g): Sine/noise/shock 75/75/151

- Max. Payload (kg): 150

Vibration test system TV 51144 / S 540

- Nominal force (N): Sine/noise 440/311

- Frequency range (Hz): 2-6500

- Max. Vibration displacement (mm): Peak - Peak 25.4

- Max. Acceleration (g): Sine/noise 1100/770

- Max. Payload (kg): 6

- Armature diameter (mm): 60

Vibration test system LDS V555

- Nominal force (N): Sine/noise 940/636

- Frequency range (Hz): 5-6300

- Max. Vibration displacement (mm): Peak - Peak 25.4

- Max. Acceleration (g): Sine/noise 100/69

- Max. Payload (kg): 25

Equipment modal analysis/acoustics

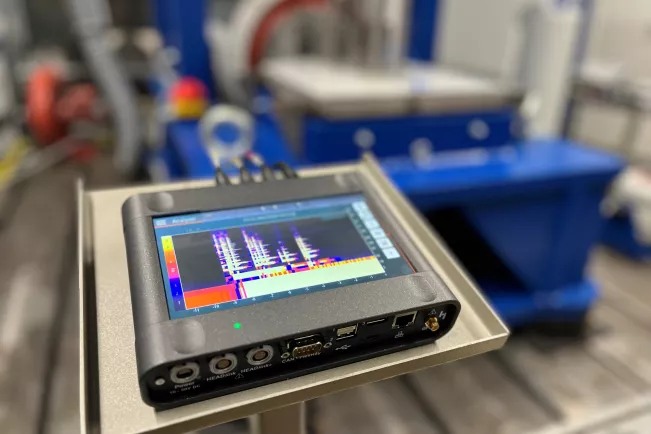

Laser-Vibrometer PDV100

Measured variable: Vibration velocity

Useful frequency range: 0 - 22 kHz

Piezoelectric vibration generator Wilcoxon Research modal F7

Frequency range (Hz): 500 - 20,000

Equipment Optical measuring systems

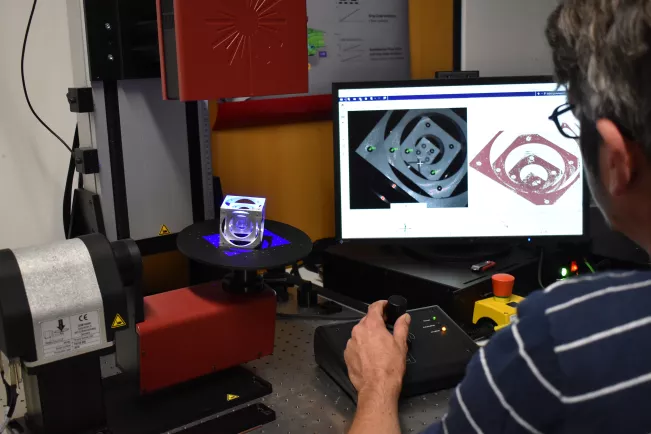

ARAMIS SRX Camera-System

- Acquisition of 2D and 3D coordinates for the analysis of statically or dynamically stressed components and samples

- Non-contact and material-independent measurement

- Area of application: For areal and point analyses of samples ranging from a few millimetres to structural components several meters in size

- Frame rate: up to 2000fps

- Camera resolution: 4096 x 3068 px

ARAMIS 5M Camera-System – static

- Non-contact and material-independent measurement of samples and components (based on the principle of digital image correlation).

- Area of application: For area and point analyses of samples with a few millimeters up to structural components with a size of several meters

- Image frequency: 15Hz - 29Hz

- Camera resolution: 2448 x 2050 px

Fastcam SA3 – High Speed - Camera

- Application: For the visualization of complex motion sequences

- 1000 fps at 1024 x 1024 px resolution

- 60000 fps at reduced resolution

GOM TRITOP

- Optical 3D coordinate measuring machine

- non-contact

- Highly mobile system with low weight

GOM TRITOP software

- Complete component analysis

- Static deformation analysis

- Target/actual comparison with CAD data

- Shape and position analysis

- Alignment

- Automated evaluation of measurement results

Measurement setup

- Scales for determining dimensions

- Coded reference point markers to determine the different camera positions

- Reference point markers for recording 3D coordinates

- Measuring volume is freely scalable from a few cm3 to many m3

Research and cooperation

In many corporate strategies, collaboration with research institutions has long been established as an important element of open innovation. When it comes to specific research ideas or supporting entrepreneurial challenges, the university is on hand as a scientific partner with its expertise.

If you are interested in a collaboration, please contact us.

Contact

Iris Groß

Dean of the Department of Engineering and Communication, Director of the Centre for Teaching Development and Innovation, Professor of Engineering Mechanics, Design Elements, CAD, Alumni Commissioner

Location

Sankt Augustin

Room

B 201

Address

Grantham-Allee 20

53757 Sankt Augustin

Telephone

+49 2241 865 306

Location

Sankt Augustin

Room

B 010

Address

Grantham-Allee 20

53757 Sankt Augustin

Telephone

+49 2241 865 302